Understanding Crash Ratings for Barriers

Table of Contents:

The Three Key Factors | K-Ratings Explained | M-Ratings Overview | Tested vs Certified vs Engineered | ASTM Standards

Security barriers, including bollards and gates, play a crucial role in protecting entry points by deterring unauthorized access and minimizing property damage during accidents. These barriers are essential for industries and sectors requiring heightened security. U.S. crash ratings provide standardized, objective evaluations of the durability of such barriers.

Crash ratings help you identify barriers that can withstand high-impact collisions effectively. If you're seeking reliable security solutions, understanding crash ratings for gates and bollards is essential. This guide will walk you through the nuances of interpreting crash ratings.

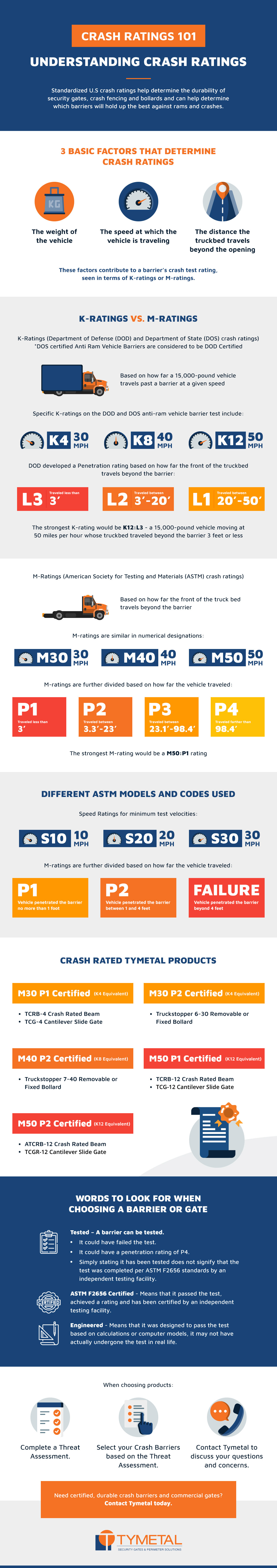

The Three Key Factors in Crash Ratings

Crash ratings depend on three fundamental criteria:

- The weight of the vehicle involved in the collision

- The speed at which the vehicle is moving

- The distance the vehicle travels beyond the barrier after impact

Some rating systems only grant certification if the vehicle travels 50 feet or less beyond the barrier. Together, these elements define the classification of a barrier's crash rating. Ratings may be expressed as K-ratings or M-ratings, so it’s important to grasp the distinction between them.

K-Ratings: Traditional Ratings

Department of Defense (DoD) crash ratings, also known as K-ratings, were established in 1985. DoD ratings focus on how far a 15,000-pound vehicle moves past a barrier at a specific speed. For K-ratings, only vehicles traveling 50 feet or less beyond the barrier qualify for certification. Higher K-ratings correspond to tests conducted at faster speeds, using the same vehicle weight and type. Specific K-ratings listed in the DoD anti-ram vehicle barrier guidelines include:

- K4 crash ratings: These denote tests at 30 mph.

- K8 crash ratings: This test speed is 40 mph.

- K12 crash ratings: These ratings apply to tests at 50 mph.

K-ratings also feature sub-classifications L1, L2, and L3, depending on how far the front of the vehicle extends beyond the barrier.

- L3 rating: The vehicle crosses the barrier by less than 3 feet.

- L2 rating: The vehicle crosses the barrier between 3 and 20 feet.

- L1 rating: The vehicle crosses the barrier between 20 and 50 feet.

The strongest barrier in terms of K-ratings is K12: L3, meaning a 15,000-pound vehicle moving at 50 mph penetrates the barrier by less than 3 feet. To interpret K-ratings, the "K" figure indicates the test vehicle's speed, while the "L" figure shows how far it traveled beyond the barrier.

M-Ratings: Modern Ratings

M-ratings have replaced K-ratings in recent years, adhering to standards set by the American Society for Testing and Materials (ASTM). Unlike K-ratings, which consider the distance the vehicle's front crosses the barrier, ASTM M-ratings evaluate how far the vehicle's payload travels beyond the barrier. Both M-ratings and K-ratings depend on vehicle size, speed, and travel distance.

M-ratings align closely with K-ratings in terms of test speeds, making it simple to compare them. A K4 and M30 rating are equivalent, a K8 matches M40, and a K12 corresponds to M50. The vehicles in these tests move at 30, 40, and 50 mph, respectively. Due to their similarity, K-ratings and M-ratings can often be used interchangeably.

M-ratings are further categorized into P1, P2, P3, and P4 grades based on how far the vehicle travels beyond the barrier:

- P1 rating: The vehicle travels 3.3 feet or less.

- P2 rating: The vehicle travels between 3.31 and 23 feet.

- P3 rating: The vehicle travels between 23.1 and 98.4 feet.

- P4 rating: The vehicle travels beyond 98.4 feet.

Compared to K-ratings, M-ratings cover longer distances, offering a more precise assessment. A K12: L3 rating is equivalent to an M50: P1 rating. Meanwhile, an M50: P2 rated beam can stop a 15,000-pound vehicle moving at 50 mph without allowing it to travel more than 23 feet.

Tested vs. Certified vs. Engineered

Pay attention to terms like "tested," "certified," and "engineered," as they carry distinct meanings and varying degrees of reliability. Here’s what each term signifies:

- Tested: Be cautious of items labeled "crash-tested." Just because a barrier has been "tested" doesn't mean it passed or meets the stated criteria. A product marked "tested" at a certain K- or M-rating may not actually achieve that rating.

- Certified: A "certified" label is more trustworthy — if a barrier is "certified" at a specific rating, it means it successfully passed the test and attained that rating. Always opt for "certified" barrier products.

- Engineered: If a product is "engineered" to meet a certain label, it means it was designed to pass the test using calculations or simulations. However, it may not have undergone actual testing, so keep this in mind.

In summary, prioritize "certified" M-ratings and K-ratings. If you encounter "tested" or "engineered" labels, inquire further: ask whether tested products met the required standards, and check if engineered products were physically tested. Without evidence of real-world testing, there's little assurance they'll endure actual crashes.

Different ASTM Models and Codes

As previously noted, ASTM employs models and codes to categorize anti-ram tests based on vehicle speed, weight, and distance traveled. Familiarizing yourself with these codes is crucial for comprehending crash ratings. Explore more about ASTM standards for vehicle security barrier crash tests.

A key aspect is the speed rating, indicated as follows:

- S10: The minimum test speed is 10 mph.

- S20: The minimum test speed is 20 mph.

- S30: The minimum test speed is 30 mph.

Next are the ASTM penetration ratings, detailing how far the vehicle moved beyond the barrier. Low-speed penetration ratings include:

- P1: At low speeds, a vehicle breached the barrier by no more than 1 foot.

- P2: At low speeds, a vehicle breached the barrier between 1 and 4 feet.

- Failure: At low speeds, a vehicle breached the barrier by more than 4 feet.

High-speed tests follow slightly more lenient standards. The codes used for high-speed penetration ratings include:

- P1: At high speeds, a vehicle breached the barrier by no more than 3.3 feet.

- P2: At high speeds, a vehicle breached the barrier between 3.31 and 23 feet.

- P3: At high speeds, a vehicle breached the barrier between 23 and 98.4 feet.

Secure Your Premises with Certified TYMETAL Barriers

When safety is paramount, you need barriers that meet rigorous standards. At TYMETAL, all our security gates and crash barriers have earned prestigious ASTM crash ratings. You can trust that our barriers have satisfied the impartial, global benchmarks of the ASTM. Shop durable crash barriers and commercial gates from TYMETAL today.

Reviewed By Chris Herold on 4/29/2021

Screw Barrel For WPC Profile,Alloy Structural Steel Conical Twin Screw Barrel,Steel Conical Twin Screw And Barrel

ZHEJIANG BOHAI MACHINERY CO., LTD , https://www.bohai-screw.com